Why Choose Flexographic Printing for Packaging?

Whether a company manufactures household products, pet food, frozen food or most other consumables, packaging is an important consideration. Packaging protects, provides storage, and defines the product. There are many types of packaging – bags, boxes, cans… It has been said you have 3 seconds to get the attention of a consumer – the package design matters! Whether its a printed Polybag or Label, the Printers job is to reproduce the design, color and detail. The package needs to “jump” off the shelf. Although there are many ways to print the package or label, one of the most popular is Flexographic Printing. So what is it?

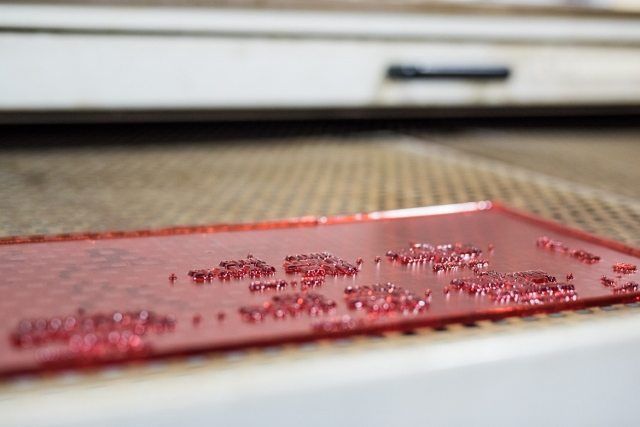

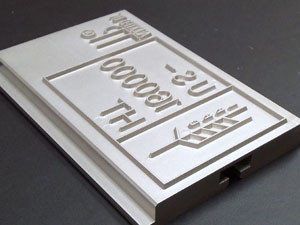

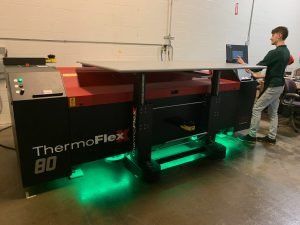

What is Flexographic Printing? In its simplest form Flexo is relief printing using soft or flexible printing plates. The plates are made from a polymer material by a process know as flexography. The plates are mounted to a press and quick drying inks are used to print on material such as polypropylene or label stock. Each color requires a separate plate.

What are the benefits of Flexographic? Flexographic Packaging offers a nimble solution which is relatively economical, offering greater profit margins, as compared to rigid packaging. In addition, It allows great flexibility in art and color choices. Flexible packaging also uses less material, which can make it environmentally favorable. It is also lightweight and easy to transport, which makes it logistically beneficial.

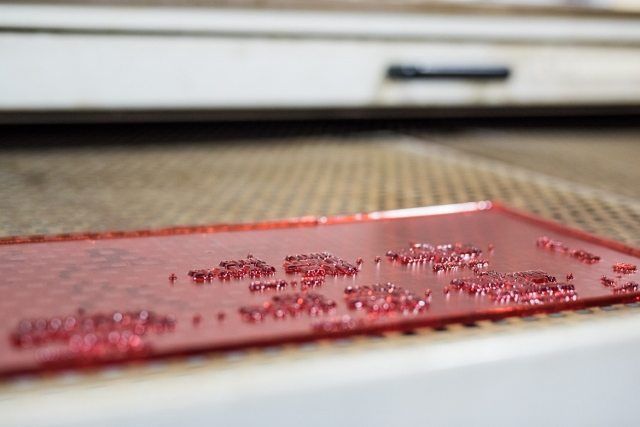

What’s the Flexographic Process? The process begins with the art or concept for the package. A Prepress Design Specialist will work with the art to make it Plate/Print ready. The Graphic Designer, with expertise in Package Design, will work to color correct, if necessary. The file is sent to the Processer where a photo polymer plate material is used to produce the soft or Flexographic Plate. The Plate is “washed” and “dried” and is ready for the Press within a few hours.

Need more information?

What is Flexographic Printing? In its simplest form Flexo is relief printing using soft or flexible printing plates. The plates are made from a polymer material by a process know as flexography. The plates are mounted to a press and quick drying inks are used to print on material such as polypropylene or label stock. Each color requires a separate plate.

What are the benefits of Flexographic? Flexographic Packaging offers a nimble solution which is relatively economical, offering greater profit margins, as compared to rigid packaging. In addition, It allows great flexibility in art and color choices. Flexible packaging also uses less material, which can make it environmentally favorable. It is also lightweight and easy to transport, which makes it logistically beneficial.

What’s the Flexographic Process? The process begins with the art or concept for the package. A Prepress Design Specialist will work with the art to make it Plate/Print ready. The Graphic Designer, with expertise in Package Design, will work to color correct, if necessary. The file is sent to the Processer where a photo polymer plate material is used to produce the soft or Flexographic Plate. The Plate is “washed” and “dried” and is ready for the Press within a few hours.

Need more information?