Stamp Types and Materials We’ve had some questions regarding Pallet/Lumber Stamps – here are some answers… What are the styles of Pallet Stamps? There are several styles of stamps currently being used for marking pallets to indicate pallets have been heat treated, meet IPPC requirements and or are for dunnage. The most common sizes produced for stamps are 1 ¼” x 2 1/8” and 2” x 4” but stamps can be made to any size to fit the application There are rubber stamps that are inked before use with a separate ink pad, these can be supplied with a flat mount or a rocker mount for larger sizes, along with various styles of handles or knobs. Some are also supplied as a hammer stamp There are self-inking styles of stamps, these will have an ink pad as part of the stamp and will ink the die while being used. They can be supplied as an upright style, commonly referred to as a grocery stamp, or as a roller stamp where the image is rolled on. Which type of Rubber is best for Pallet Stamps? There are different types of rubber used to make the stamp dies, natural rubber and buna rubber, and some people will use photopolymer to make the stamp dies. All provide different characteristics and benefits. Ink choice needs to be considered when choosing the rubber type used Natural rubber is the most used. Latex based; it will provide a softer material surface that’s helps provide a better image on a rough wood surface. Natural rubber can also be supplied with a ribbed back that will be used to snap and hold into place on the stamp mount, making it easier to change dies when they wear out. Good abrasion resistance and tear resistance, fair solvent, and oil resistance. Buna rubber is a harder durometer material. It is a synthetic material that will be more resistant to the corrosive ingredients in the inks used. While it will hold up better, the harder surface makes it less forgiving when stamping a rough surface, it will not be as conforming when stamped. Excellent abrasion resistance, good solvent, and tear resistance Photopolymer is a synthetic polymer. While it may provide the best image quality, it is also the most susceptible to abrasion and environmental (ozone) issues. Poor abrasion resistance, fair tear, and solvent resistance. What type of Ink should be used with Pallet Stamps? There are several types of inks used for stamping wood. Rubber stamp ink, it is used for stamp pads and for self-inking stamps, it will have a slower dry time to avoid drying out on the pads, lower solvent (alcohol) content, designed for use with natural and buna rubber. Higher in cost. Stencil ink, quick drying. Used by many in the pallet industry because it is lower in cost, but it is much higher in alcohol content and will cause the stamp dies to swell, become gummy, and produce a lower quality image. This information does not cover all the stamp styles and materials available but includes the most commonly used. Every application can be different, we hope this will provide a good reference for you when deciding what best fits your need. EMAIL SALES@EXCELSIORMARKING.COM to learn more.

As a designer and maker of business signs that meant looking at the materials we use, and determine if we could integrate more recycled and reusable. Interestingly, this meant going back to some tried and true options – wood and metal. And cutting down on materials used. So, what is sustainable design? Simply put it’s design that offers “responsible interaction with the environment to avoid depletion or degradation of natural resources and allow for long-term environmental quality.” We began designing Signs using wood and metal sheeting, metal frames, wood plaques, and metal lettering. We tested and produced ADA/Braille Signage using UV Print technology with wood and metal. We produced Awards and Recognition displays combining natural materials and recycled, locally sourced acrylics to achieve the aesthetics and sustainability goals. In addition we produce Office Signs ,that traditionally have used 2-3 layers of materials, that use one layer of material. Our process can produce raised print, Braille and even design textures in one step on layer of material. Here’s a few more ideas… By using cut aluminum lettering we upgraded the look and environmental impact. Another trick was to use recycled materials to create an impactful design.

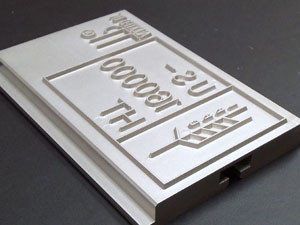

Call it Marking, Stamping or identifying; every Wood Pallet and/or Plastic Pallet that travels globally must be marked with an ISPM approved mark. The International Standards for Phytosanitary Measures – ISPM mandates this fact. The reasons for the mark is clear – to reduce the risk of the introduction and spread of pests, via wood pallet. Each item must be treated either by Heat Treatment or Chemical Treatment (Methyl Bromide). The problem arises when the “How” to mark the Pallet comes into play. The Mark, indicating treatment, varies by country. In general it will include: -The symbol (IPPC) – Country Code – Certification Agency Code – Treatment code (HT or MB) Always check with your Certifying Agency for the exact standard. From these guidelines, the search for the perfect marking solution was born. The challenge is to find a method that will work in a dusty, outside environment. In addition, depending on where the Pallet manufacturer is located, air temperature may need to be considered. There are a few major ways to mark wood pallets. All have advantages and disadvantages. They include Branding, Stenciling or Stamping. Branding Branding uses a Iron with a heated, metal die to burn an imprint into the pallet. Heavy duty Branding Irons can be hand held or machine mounted. Branding creates a solid impression. Generally the brand will include the two letter country code (e.g. DE for Germany), the regional identifier (e.g. NW for North Rhine-Westphalia) and a registration number issued by the regional phytosanitary authority to the packaging container manufacturer, the packer or the consignor (unique number beginning with a logo. Learn more about the approved mark from your certifying agency. Custom branding dies are made of steel or hard metal that can withstand the high temperatures. Electric and Propane Branding Irons come in different wattages. A higher watt iron will allow a quicker process, with less down time. Branding entails more of an investment than stamps or stencils. All dies are custom machined, and the heavy duty Branders are also an investment. Once set up to Brand, the equipment can last several years. Stamping First, and probably, most common is marking with a Rubber Stamp. There are several types of rubber stamps; knob handle, self inking, and roller. The image is clear and visible, and with proper care, the stamp is a good solution. However, the process can be relatively slow since each pallet is stamped individually. Stenciling Stenciling is another solution for marking wood pallets. A laser cut, custom stencil is positioned on the pallet; Ink or paint is applied; and the stencil is removed. When applied carefully, a good mark can be achieved. e best solution to marking pallets and lumber. The printer can be programmed from a PC and allows wireless marking. Printing is quick and consistent. For larger operations, inline printers can be machine mounted. This option does require an investment and a more “innovative” business philosophy. One early adopter had this to say; (the hand held printer) has “given us the ability to quickly mark our pallet and crating products with very little effort… Markings are clean and clear, showing a professional look our customer base now demands.” There has also been some resistance to accept the printed marks by some in the Pallet Industry, but that seems to be subsiding as more Hand Held Printers are used.

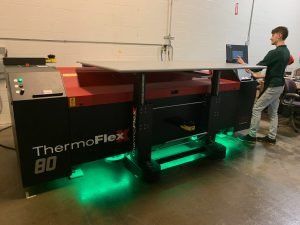

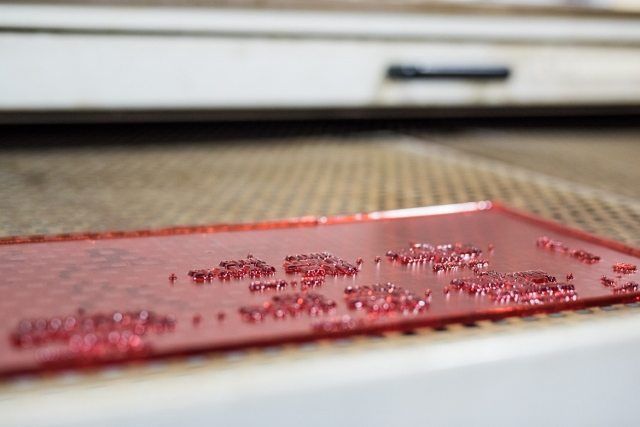

Currently, the global flexographic printing market is growing at a consistent pace, with a projected value of over $20 billion by 2025. At the forefront of this growth is the wide web press market as its versatility provides important applications in the world of consumer goods packaging and labeling. “We knew about the growth opportunity within the industry and made it our focus to enhance our capacity, speed, quality, and resolution,” said Dave Sutter, owner of Excelsior. Combining our new focus and our extensive experience in the wide web market, we set forth to improve our plate making capabilities on the digital side to better serve current and potential customers. The team needed the right technologies to cover a wide variety of clients and industries. In 2020-2021 we went to work and invested in new, state of the art equipment and software. This investment included installation of a new digital imager, which produces plates at resolutions of up to 5080 dpi, to compliment the existing imager that produces plates at resolutions of up to 4800 dpi. With the new equipment installed into our workflow, we are able to offer higher quality resolutions unlike before as both imagers improved print quality by 61.29% and 44% respectively over competitive offerings. Our high dpi imagers produce more intricate high-quality photopolymer plates that allow our customers to see a marked difference in the quality and detail of the products they are printing. “We were already above our competitors with 4800. Now, we are a step even higher at 5080, putting us at a greater advantage.”, Operating with Efficiency In the current flexographic market, it’s difficult to compete with us. Multiple digital imagers allows us to increase capacity and improve turn around times. Our centralized Shop offers high tech solutions from experienced Designers, Technicians and Customer Service. Tami Warlop, our Team Manager, has over 25 years experience in Prepress Services and Brian Collins, Technical Manager has over 25 years in Prepress and Press side. We are, and have been, ISO 9001-2015 Certified, which is a newer requirement for many print jobs. Through this intensive focus on Quality Assurance and Control, customers can rest assured that Excelsior’s plate manufacturing process will always be consistent with every plate it makes. Not only will every single plate print perfectly, but also each batch will be presented at maximum quality. Our Team of experts, combined with state of the art Flexographic Plate equipment, work with each Customer to ensure the best supplier experience. To learn more call 800-433-3615, email Tami Warlop, Team Manager or Brian Collins, Technical Manager. Founded in 1905, Excelsior Marking is a pre-press printing service firm located in Akron, Ohio. For the last 50 years, Excelsior has made a name for itself thanks to its high-quality flexographic printing plates. As one of the only prepress houses that isISO 9001:2015 certified with quality systems, Excelsior continues to provide top-quality products and services to its clientele. More Here

Two years and counting… So here it is almost 2 years after it all started. Many business are recovering and/or reopening. People are returning to “in person” work. Many businesses are having difficulty finding workers. We are dealing with a new virus variant. The government is “printing money” to keep the economy going. It’s somewhat controlled chaos. The next few years will be interesting for Small Business. In February 2021 CBS News reported… “Three out of every 10 small businesses in the U.S. say they likely won’t survive 2021 without additional government assistance during the coronavirus pandemic, a survey from the Federal Reserve Bank shows. Considering there are roughly 30 million small businesses in the U.S., that means 9 million small firms are at risk of closing for good this year.” As an update a June 2021 Fact Check report quoted a Harvard University-based project called The Economic Tracker. The online platform provides data about real-time economic trends and uses financial transaction activity to suggest whether a business has closed. As of the week of June 8 2021, the Tracker showed there were 37.5% fewer small businesses open nationwide compared with January 2020, two months before the pandemic hit the United States. As a small business we are proud and grateful that we have survived and, in some ways thrived during this crisis. The downturn gave us a chance to re-group. First, we upgraded technology and equipment to keep up with added demand in our Prepress Services (Packaging) area. Second, we entered new markets to help with the crisis(PPE). Third, we are reviewing goals in our Contract Machining area to accommodate new markets. Finally we increased our E-Commerce presence. All this was to keep current with the new normal. To us the most important part of this was our people Keeping them healthy and employed. These people are like family; their families are like family… I also know that without these people, we can’t serve our customers. Consequently, our customers can’t serve their customers… and it goes on. (The simple definition of Supply Chain). With the help of Federal PPP, State and County Grants, and a lot of “thinking outside the box” we have continued to grow. Although Covid is still with us, I’m optimistic that we have learned how to navigate the health crisis. I believe and understand that it’s not going to be a straight line out of this. There will continue to be ups and downs, opens and closes, speed ups and slow downs – you get the idea. To us, that’s what you get when you go into business. You may be asking “how did you do this”. Reflecting back, it’s a blur and a Team effort. At times we would look around at my coworkers and think “why do you do this?” One word comes to mind CULTURE. Excelsior Marking stays together because we have built a culture of respect, empathy, and perspective for each other, and our Customers. These are a few guideposts I maintain to get through. First, Stay presen t and remember the Law of Impermanence – everything is constantly changing. The good times will come and go/the bad times will come and go. Be Positive – Think Positive – Do Positive (this saying is painted on one of my Manager’s office walls) Positivity is a choice to make every day. There is something good in everything. Even a closure will move you to the next opportunity. No one regrets what they did, they only regret what they didn’t try. Next, watch for Burnout . Stress on the job for a prolonged period affects our ability and desire to do our jobs. We needed to learn to be empathetic, take breaks, and breathe. A job is what we do, it’s not who we are. This attitude needs to come from the Top. If you manage people, you need to be the model. A few times I caught myself saying “This job is not life threatening”! Always, be open and communicate, communicate, communicate. None of us know all the answers. None of us have been through a pandemic. We will all make mistakes and that’s ok. I stopped “posting” written information because it changes every day and confused all of us. Every morning I check my news feed and walk around the Plant to hear if anyone has heard anything new. (It’s called managing by meandering, and I highly recommend you try it) Finally, Celebrate the “Good Stuff” . Holidays, Birthdays, Weddings, Babies , the Super Bowl, St. Patrick’s Day, Memorial Day…all happened during Covid. Get the pizza, make the cake, bring in the donuts and celebrate! One last thing, if you’re one of our loyal Customers or Vendors, WE THANK YOU FOR YOUR LOYALTY”! To all others be well!

Prior to Covid19 most PPE was used by Medical Professional. Most PPE was sourced from overseas. The worldwide spread caused an initial shortage in the United States. To answer the call, many US manufacturers’ (including Excelsior Marking) retooled to fill the gap. Currently, Americans are being encouraged to add Face Coverings to Social Distancing and Hygiene protocols. So “what’s the best covering?”. The honest answer – “it depends who you ask”. Here’s a brief summary of some of what we’ve found regarding non-medical Face Covers – Acrylic Shields (which cover eyes, nose, and mouth) and Cloth Masks (which cover nose and mouth). Both are viable options and may offer a barrier to the spread of airborne viruses. Nothing can offer complete protection, and both are meant to protect others. Acrylic Face Shields Generally made from clear, thin, acrylic with a band which fastens around the head. Shields should reach above the forehead, below the chin, and wrap partially around the side of the face. Face Shields are often worn by medical professionals to prevent fluids from getting to eyes, nose and mouth. Recently, Shields are being seen worn by the general public.One study* of their effectiveness reported a 96% reduced exposure of cough aerosols with a distance of 18”. Shields do not replace the need for Social Distancing and good hygiene. Advantages Lightweight Offers good airflow Reusable – Cleans easily Covers Eyes, Nose and Mouth Limits eye touching Less need for “adjustments” than with a Face Mask. Allows for better communication as the mouth is visible. Can be worn with eyewear – less fogging Cloth Face Covers Todays’ non- medical Face Masks are made from cloth. Generally, cotton or polyester blend. A mask is secured around your ears and will cover your nose and mouth. The CDC reports that used in conjunction with Social Distancing and good hygiene, a Mask may provide protection for those around you. Advantages Lightweight Easily forms to the face Commonly available Reusable – wash/launder after each use. Convenient Widely accepted Both Shields and Masks may provide virus protection. Which to choose depends on the situation and the wearer. *published 6/24/2020 “Health Essentials form Cleveland Clinic” Excelsior Marking has pivoted its operations to provide PPE during the Covid19 crisis. To learn more visit DeskGuardShop.com .

ULTRA-E HD platemaking will take your flexo print to ULTRA HIGH levels. Combining industry leading 4800dpi imaging, innovative flexo dot screening and skilled flexo prepress professionals, ULTRA-E HD will improve your print color and clarity instantly. Using proven direct to plate technology, ULTRA-E HD consistently produces high quality photopolymer plates at 23 million pixels per inch. Comparing that to 16 million pixels for normal HD and 5.7 million pixels for traditional digital platemaking shows ULTRA-E HD images with about 40% more data per square inch. More data. Better imaging. Better plates. Better print. Learn more.

A product Code or Mark is a unique identifier, assigned to each finished/manufactured item. Today, most, if not all, manufactured products require some type of identifying code, mark or tag. Whether it’s an official government requirement, to keep track of inventory or simply to identify an asset. Sounds simple, but depending on the product, it can be challenging. Here are 4 questions to ask for better product Coding, Marking or Tagging. What needs to be marked, coded or tagged? It’s important to know the type of product substrate the code/mark/tag will be applied. Is the product plastic, wood, metal or other? This will help determine which marking method is best – print, stamp, tag… Which method will provide long lasting results? It is also important to know if there are any special marking regulations for the product. Are there size requirements? Does the mark need to be etched into the item… Where should the Code, Mark or tag be applied. Do you need to code/mark the outside, inside, top or bottom of the product? This can be very important for display and inventory control purposes. How is the code, mark or tag going to applied? Are the items used indoors or outdoors? Does the mark need to be engraved, stamped, branded, labeled or printed? When does the code, mark, or tag need to be added – before, during, or after production. This is important when planning the production process. Do the parts need to be marked before or after assembly? For more information about Marking/Coding/Tagging products ask the experts a Excelsior Marking.