Pallet Marking 101

Stamp, Stencil, Brand or Print?

Call it Marking, Stamping or identifying; every wood Pallet that travels globally must be marked with an ISPM approved mark. The International Standards for Phytosanitary Measures – ISPM mandates this fact. The reasons for the mark is clear – to reduce the risk of the introduction and spread of pests, via wood pallet. Each item must be treated either by Heat Treatment or Chemical Treatment (Methyl Bromide). The problem arises when the “How” to mark the Pallet comes in to play…

The Mark, indicating treatment, varies by country. In general it will include:

-The symbol (IPPC)

– Country Code

– Certification Agency Code

– Treatment code (HT or MB)

Below are some sample marks. Check with your Certifying Agency for the exact standard.

From these guidelines, the search for the perfect marking solution was born. The challenge is to find a method that will work in a dusty, outside environment. In addition, depending on where the Pallet manufacturer is located, air temperature may need to be considered. There are a few major ways to mark wood pallets. All have advantages and disadvantages. They include Stamping, Stenciling, Branding and Printing. By looking at costs and benefits, one of these methods should fit the manufacturer’s needs.

Stamping

First, and probably, most popular is marking with a Rubber Stamp. There are several types of rubber stamps; knob handle, self inking, and roller. Rubber Stamps are one of the most affordable solutions. They are also relatively easy to use. The image is clear and visible, and with proper care, the stamp is a good solution. However, the process can be relatively slow since each pallet is stamped individually. In addition, the correct amount of pressure is necessary to create a good impression. Perhaps the biggest problem with rubber stamps is after several impressions, if the stamp is not cleaned of debris, it will be coated with sawdust. In addition, if the correct ink is not used, the ink solvent may cause the die to separate from the base.

Stenciling

Stenciling is another solution to marking wood pallets. A laser cut, custom stencil is positioned on the pallet; Ink or paint is applied; and the stencil is removed. Stenciling is also one of the most affordable solutions. When applied carefully, a good mark can be achieved. Again, this process can be time consuming. In addition, if care is not taken, excess ink and paint may cause the area to be soiled.

Branding

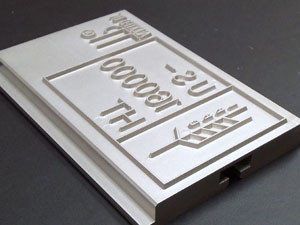

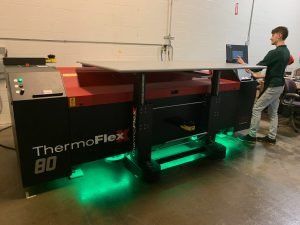

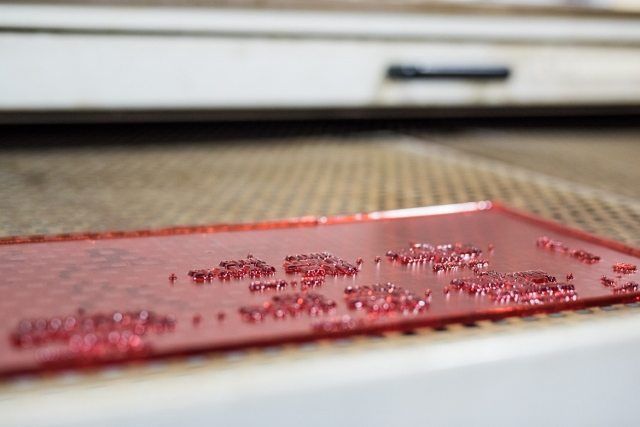

Branding is also a way to mark Pallets. A heated, metal die with the ISPM approved mark, is pressed on to the pallet. The impression is burned into the wood. Heavy duty Branding Irons can be hand held or machine mounted. Branding, arguably, creates the best impression. There are no inks involved, so it is a relatively clean process. Custom branding dies are made of steel or hard metal that can withstand the high temperatures. Electric and Propane Branding Irons come in different wattages. A higher watt iron will allow a quicker process, with less down time. Branding entails a significant initial investment. All dies are custom machined, and the heavy duty Branders are also an investment. Once set up to Brand, the equipment can last several years.

Other, less used, ways to mark include Ink Jet printers. The pallet passes by the printer and a mark is applied. This also entails a substantial investment in equipment and training. The pallet manufacturer will need to have some type of conveyer system. In addition, the environment of a pallet operation can create challenges for the machine. Although some type of printing system can be advantageous, it may not be practical for some manufacturers.

Although it sounds simple, marking a pallet can be a challenge. What is clear, whether you stamp, stencil, brand or print, every pallet that travels globally must have an approved mark.

Sources: ISPM 15, ALSC

Author is the Marketing Director for Excelsior Marking, a marking products manufacturer and NWPCA member.